At different times throughout the course we have other activites to complete- including making oars.

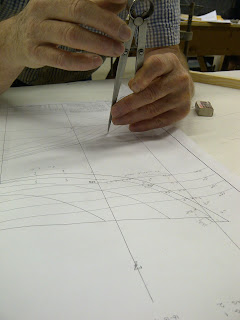

It turned out to be a thoroughly enjoyable process and gave us room to put our own stamp on the finished product. I chose to make a paddle for a SUP Board (http://www.supsurfmag.com/) out of the Sitka Spruce we were provided with. This wood is relatively light and strong. I first had to square of the length of Spruce and then work out how to bend the shaft near its base to crated the 'crank' seen in SUP and outrigger paddles. I chose to cut 28" long kerfs into the base of the shaft and then insert more Spruce. This allowed the shaft to be bent around a 'former' and glued into place.

Once the glue had set and any exces cleared off I glued on two pieces of spruce and two pieces of mahogany either side of the cranked section. These would form the blade of the paddle.

The shaft had to be tapered from its base to its peak and then shaped the shaft into an elipse which turned through 90 degress from just above the blade to the position on the handle. This is a process involving many small stages that if followed result in a smooth and progressively shaped shaft. Its no good having a wonky/ lumpy shaft I think you'll agree.

The blade then needed to be shaped and this was a delicate operation as it was about 4mm thick at the edges. By Thursday evening I have shaped a great looking paddle and I will spend Friday constructing the handle and laying fibre glass over the blade to strengthen it. I cant wait to use it when paddling a board and I already have ideas about different methods of construction for a similar paddle.