Lofting is when full scale drawings of the boat are produced on huge pieces of hard board. I worked with David to loft his 19'6" Caledonian Yawl which took the best part of a week and a bit. We lofted three different views of the boat on the same piece of hardboard- Profile (side on), Half Breadth (Birds eye view) and Body Plan (viewed from the bow/stern), after which the lines resembled spaghetti thrown at a wall, as Mike our instructor would say.

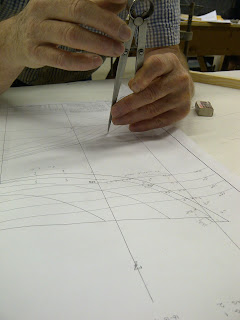

Pencils, rubbers, rulers of all sizes, lofting batons, wooden batons and quick clamps became very familiar to us as we used them to manipulate the table of offsets provided by the boat's designer. We plotted these points on our huge grid and drew lines that connected into what we thought were fair and would produce a good looking and functional boat.

We then used the lofting to take full scale measurements used to produce the plywood moulds around which the boat will be constructed. There were seven moulds in all and it was important that all of our lofting and mould measurements were exact. A quick way to transfer the shape of the moulds onto the plywood was to tap small nails on their sides into the lofted lines. The plywood is then laid on top and a after a few whacks with a mallet the imprints of the nail heads are left on the plywood. These imprints are then connected with a lofting baton and a pencil and the shape of the moulds can be cut out.

Doing this for over a week produced many furrowed browns and gasping yawns as we tried to soak up the information and work load. David and I worked well as a team with my drive and his considered thoughts and calculations. I cant wait to start building the boat for real and to see these lines become a tangible 3D form.

No comments:

Post a Comment